Slipper ptfe Composite seals

|

SLIPPER: Neuflon-ptfe compound seals

|

|

|

APPLICATIONS

In high speed and pressure fluid dynamics even in absence of lubrication, in analogical regulators and controllers, servo-systems and for all those uses where general high reliability is required

|

|

Double action sealing

Very low friction

No stick-slip

Installation in closed grooves and minimal encumbrance

Supplied in all sizes and many profiles

Long life

|

High reliability

Resistance to the "diesel effect"

Ample chemical and termal resistance

High extrusion resistance

No sticking

|

Parker O-Rings

HD Slippers Srl suggests the use of high quality Parker O-Rings within its Slipper Seal kits.

|

| PRODUCTION PROGRAMME |

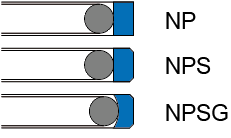

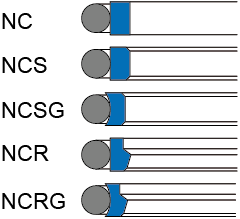

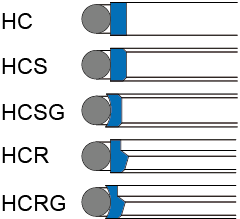

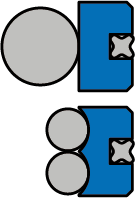

PISTON Slipper

|

|

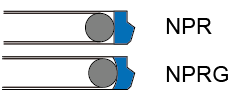

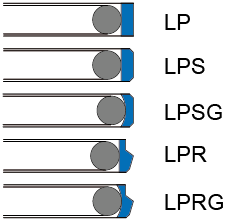

ROD Slipper

|

|

|

Standard SLIPPER N series

- Used in hydraulics and pneumatics

- Max. pressur 800 bar and over in particular conditions

- Speed up to 5 m/sec

- Temperature range -60 a +200 °C

The N series is suitable for the most difficult conditions of use and the most extensive clearence

resizing is needed if installed in closed grooves

|

|

|

|

High Response SLIPPER H series

- Used in hydraulics and pneumatics

- Max. pressur 600 bar and over in particular conditions

- Speed up to 5 m/sec

- Temperature range -60 a +200 °C

The H series is suitable for the most difficult conditions of use and is suggested instead the N series when a faster response to the pressure is required

resizing is needed if installed in closed grooves.

|

|

|

|

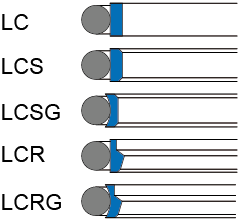

Light SLIPPER series L

- Used in hydraulics and pneumatics

- Max. pressure 100 bar and over in particular conditions

- Speed up to 5 m/sec

- Temperature range -60 a +200 °C

The L series is the standard for use in pneumatics. It can be used in oleodinamics too, mantaining the clearance at a minimum

|

|

|

|

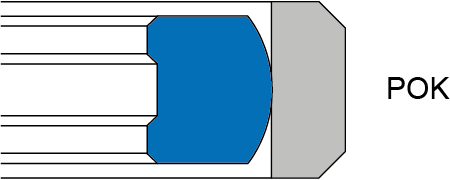

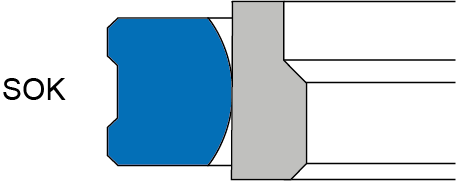

Heavy SLIPPER OK series

Slipper composite High Stability seals

Hydraulics

Pressure Max. 800 bar and over in particular conditions

Speed up to 5 m/sec

Temperature range -60 a +200 °C

|

|

|

|

Ultra-Light SLIPPER series

Little encumbrance Slipper seal to fit O-Ring grooves

Used in hydraulics, pneumatics and chemical industry

Max. pressur 300 bar and over in particular conditions

Speed up to 5 m/sec

Temperature range -60 a +200 °C

When O-Rings stick, wear or extrude. It also allows the use in dynamic applications of O-Rings whose compound is for static sealing only

|

|

|

|

ROTOSLIPPER

Used in hydraulics

Slow rotational movements, fast translational movements and combined roto-translational movements

Max. pressur 800 bar

Temperature range -60 a +150 °C

|

|

|

|

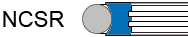

Slipper NPQ

double acting piston seals

oleopneumatics and all applications where separation of different fluids is required

Pressure max. 400 bar

Speed max. 0.5 m/sec

Temperature range -35 a +100°C and more with speciale compounds.

|

|

|

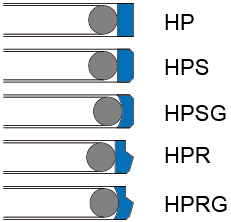

GUIDE TO CHOOSING THE RIGHT SLIPPER PROFILE

|

Double action sealing. In dynamic applications it shows optimum sealing in both senses

|

|

Double action sealing. In dynamic applications it shows optimum sealing in both senses. more suitable for high speeds. At low speed and in static conditions this profile performs better than the preceding one |

|

Single direction seal. In dynamic conditions it presents optimum sealing on the one hand and on the other it facilitates the return of the film of oil adherent to the sliding surface. Generally used for rod sealing in hydraulics applications |

|

these profiles guarantee a longer life of the seal in conditions wherein constantly frequent levels of extreme pressure are reached

|

|

Double action seals for keeping different fluids separate, e.g. gas / oil

|

|

Single acting special seal for pressure intensifiers, water cutting and pressure multipliers

|

|

The technical-application data specified in catalogues, documentation and on this website are the result of more than forty years of experience and laboratory tests. The seal types suggested are the result of laboratory tests and thousands of field tests; however, the working conditions foreseen may not coincide with those of new applications and so lead to unexpected results. Therefore, HD Slippers Srl shall not be held responsible for the failure of sealing components that have not been tested under the actual working conditions. For new applications and the consequent manufacturing of specific seals, the user must conduct tests under the actual working conditions in order to approve the validity of the chosen solution. HD Slippers Srl guarantees the repeatability of the characteristics of seals tested and approved, except for subsequent modifications of applications and/or equipment and/or its components and/or processes, by the customer or a third part.

|